Production Planning

Scientifically Applied

Advanced scheduling that harmonizes Heuristics / Genetic Algorithm derived optimality with the tacit knowledge of your seasoned planners.

Core Capabilities

Precision Production Orchestration

Advanced optimization that balances industrial challenges with practical realities on the ground.

01

Constraint-Aware Sequencing

Mathematically accurate scheduling that integrates sequence dependencies, equipment constraints and human expertise.

02

Multi-Objective Synchronization

A unified solution that balances throughput, cost efficiency, and flexibility.

03

Closed-Loop Adaptation

Adaptive models that continuously improve by learning from real-world results and variances.

Why It Works

Detailed Production

Mathematically precise scheduling that adapts in real time to your operations.

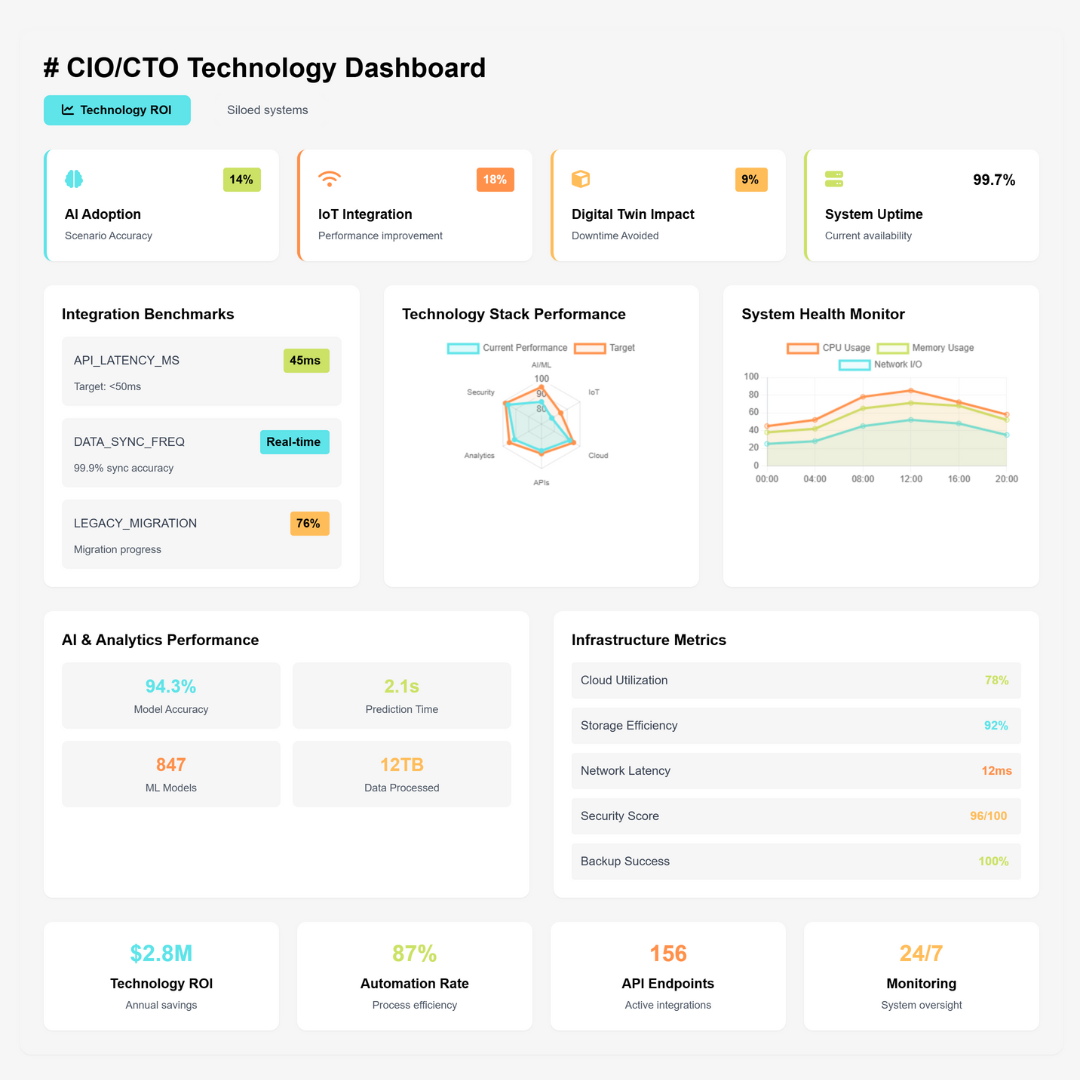

Constraint-Optimal Scheduling

MILP-driven planning that optimizes between competing objectives of capacity utilization, on-time delivery, serviceability resulting in about 15% improvement in production and 10% improvement in lost sales.

Human-Algorithm Collaboration

Planners can adjust algorithmic recommendations with recorded reasoning, ensuring transparency while applying their expertise.

Live Performance Adaptation

Reinforcement learning adjusts for changes in demand and supply in weekly time buckets.

Multi-Plant Synchronization

Efficiently manage critical resources across facilities using decentralized optimization techniques.

How Production Scheduling

Embeds in Your Operations

Seamlessly links strategic production targets with real-time shop floor execution.

-

Manufacturing Data

Connect Live -

Optimization Rules

Customize -

Scenario Analysis

Automate -

Bottleneck Forecasts

AI-Driven

Your Shop Floor, Digitally Mirrored

Real-time ingestion of MES/SCADA data (OEE, tool wear rates, energy consumption) through Apache Kafka pipelines with event-time processing.

Automatic mapping of your unique constraints – from chemical batch dependencies to union break schedules – into optimization parameters.

- Works with SAP PP-PI

Your Physics, Encoded

Define sequence-dependent changeover matrices (e.g. 4hr cooling period between alloy grades) as hard constraints.

Dynamic priorities that shift in real-time during high demand or limited supply.

- Drag-and-drop constraint builder

- Version-controlled rule sets

Stress Test Before Committing

Run Monte Carlo simulations on your digital twin to evaluate schedule robustness against:

- Machine breakdowns (MTTR/MTBF - based)

- Rush order insertion

- Absenteeism patterns

Visualize Pareto frontiers showing trade-offs between makespan, energy cost and labor utilization.

- Compare top 3 schedule options

- Export risk reports to PowerPoint

See Next Week's Fire Drill Today

Topological analysis of your production network identifies emerging constraints using:

- Centrality metrics for resource criticality

- Petri net simulation for cascade effects

Recommends buffer stock positions or preventive maintenance to avoid disruptions.

- Alerts for >80% resource utilization

- Integrates with CMMS systems

Built for Supply Chain Realities

Algorithms that decompose large-scale problems into tractable subproblems, ensuring global optimality with warm-starts derived from historical patterns.

GPU-accelerated chance-constrained programming evaluates 10,000+ schedule permutations per second, quantifying risk exposure for volatile demand scenarios.

2000+ Optimized Supply Chains

Why Clients Trust Us

- 120% Higher AI Adoption

- 92% Planner Satisfaction

Inquizity’s constraint-aware planning slashed our production downtime by 40% while boosting throughput.

Rahul Mehta

Plant Head, Automotive Component

Capacity utilization in 3 months

Their hybrid algorithms reduced our safety stock by 28% without compromising service levels.

Priya Kulkarni

Supply Chain VP, FMCG

Order fulfillment rate

Dynamic route optimization cut our last-mile costs by 22% while improving delivery ETAs.

Arjun Reddy

Logistics Director, 3PL

Fuel efficiency gains

Benchmark Your Scheduling Intelligence Quotient

Discover how your planning measures up against MILP-optimized benchmarks and the potential for tighter utilization.