Dispatch & Replenishment Planning That Ensures Inventory is at Right Place at the Right Time

ALCHEM-I synchronize multi-echelon replenishment with real-world execution constraints to ensure perfect stock positions on time and at the right level.

Core Capabilities

Precision Inventory Orchestration

Optimized movement of goods across your network to ensure perfect stock levels at perfect timing and least cost.

01

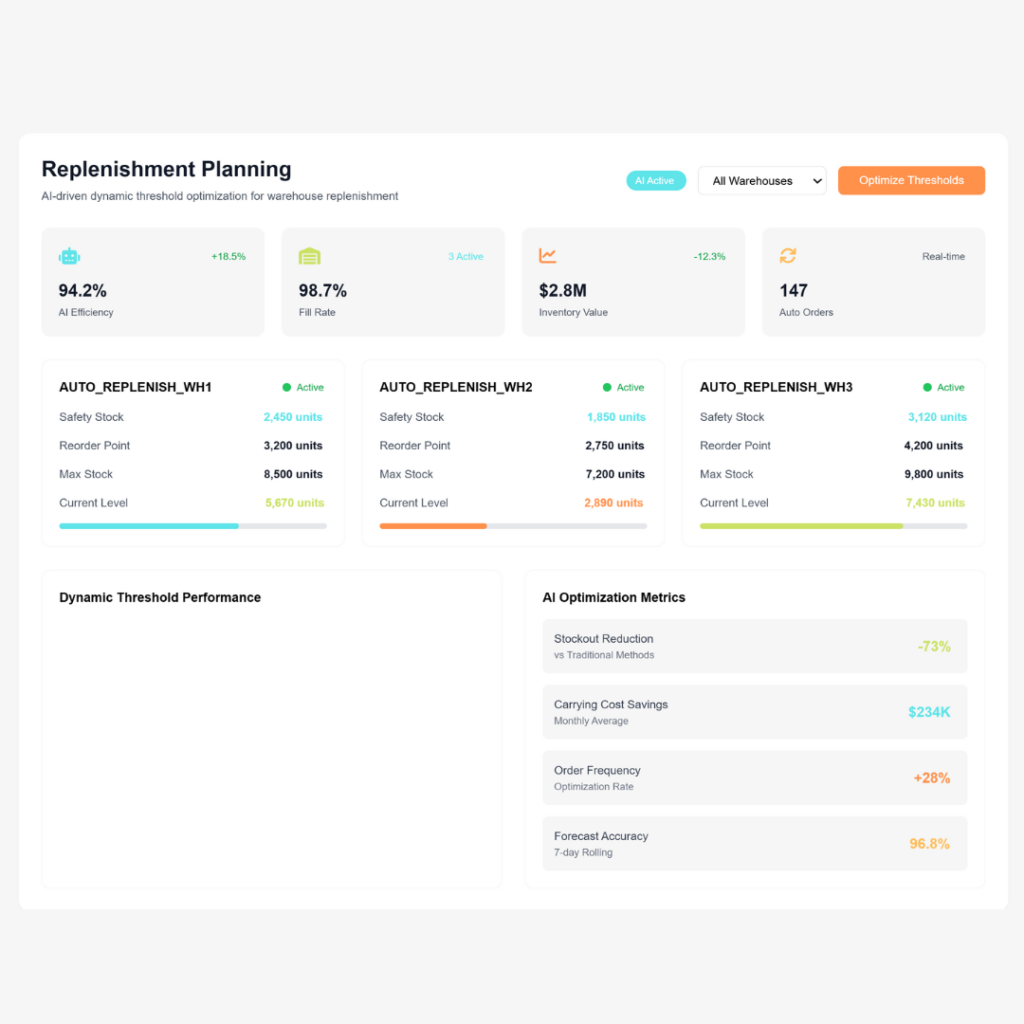

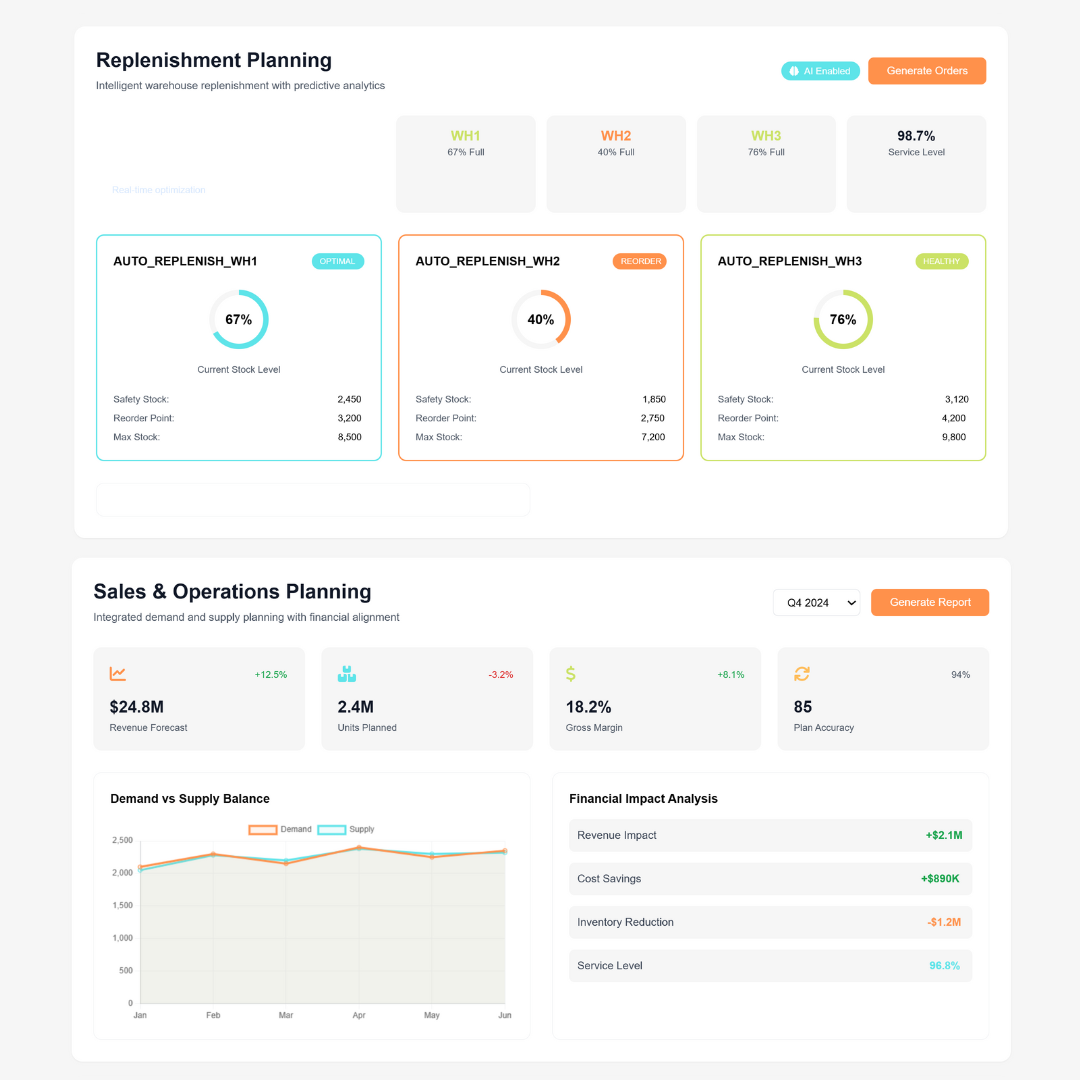

Decentralized Inventory Intelligence

Dynamic inventory norms (DDMRP) basis velocity of sales to signal automatic replenishment requirement at various nodes of the supply chain.

02

Frictionless Flow Optimization

Selection of the optimal source destination combination to minimize cost and maximize serviceability.

03

First-In First-Out Allocation

Prioritize aging stock dynamically to ensure no manual ‘sell-by’ triage or write-off surprises.

Why It Works

Multi-Echelon Inventory Optimization

Dynamic inventory movement that adapts with your supply chain from manufacturing units to warehouses, depots and distribution centers.

Real-Time Load Building

3D bin-packing algorithms + live pallet dimensions → 12% higher trailer utilization.

Constraint-Aware Allocation

Integrates cold-chain restrictions, hazmat rules and workforce skill requirements into every recommendation.

Emergency Rebalancing

Uses prescriptive analytics to address stockouts by recommending transshipments before issues escalate into critical alerts.

Carrier-Agnostic Execution

API-enabled connectivity with 50+ TMS/WMS platforms, allowing seamless provider switches without the need to replan.

How Dispatch Integrates with Your Logistics

End-to-end integration, from warehouse management through last-mile execution, approaching inventory movement as a continuously optimized process.

-

Network Visibility

Live -

Replenishment Policies

Adaptive -

Optimization

Multi-Modal -

Automation

Exception

Monitor Your Inventory in Real Time

Consolidates data from warehouse management systems, in-transit telematics and retailer POS into a unified control tower.

Auto-classifies inventory by velocity, shelf-life urgency and demand variability for dynamic prioritization.

- Works with Manhattan WMOS

- Handles 15-minute data latency gracefully

Rules That Learn from Your Network

Machine learning adjusts ROP/ROQ parameters weekly based on supplier lead time volatility and forecast accuracy trends.

Containerization logic auto-optimizes pallet builds for import-heavy operations.

- Perishability countdown timers

- Hazardous material constraints

Beyond Idealized Load Plans

Evaluates cost/service tradeoffs across LTL, FTL, intermodal and air freight options in a single optimization horizon.

Respects real-world constraints like trailer temperature zones and dock door schedules.

- Driver HOS compliance checks

- Cross-dock opportunity scoring

The 20% That Needs 80% Attention

Auto-resolves routine replenishment (80% of cases) while flagging critical exceptions like border delays or order splits.

Prescribes resolution options: transshipments, expedited freight or demand shaping.

- Customs clearance predictors

- Risk-scored exception tiers

Architecture of Continuous Flow

A distributed optimization engine that treats your supply network as a dynamic graph, recalculating shortest paths as constraints evolve.

Federated learning preserves node-level autonomy while achieving global objectives, no central point of failure in your logistics.

Outperform Your Current OTIF by 15%+

Prove it in your network – we’ll analyze your last 90 days of shipments and identify exact leakage points in your current replenishment logic.